Usefull Information

Frequently asked questions

- What is the difference between original and compatible consumables?

- Can use of not original consumables spoil the printer?

- Advantages and disadvantages of CISS (Continous Ink Supply System).

- What is cartridge refilling?

- What is cartridge reconstruction?

- What can cartridge refilling cause?

- How to consider what to do refilling or reconstruction?

- What inks to chose?

- What does laser jet cartridges drum’s speed of wear out depend on?

Cartridge’s construction

Useful information about care for printer and storage of cartridges

History of printers

Compatibility table

FAQ

1. What is the difference between original and compatible consumables?

Original consumables are being produced directly by the producer of the technique with the same brand as the technique (for example HP, Canon, Epson, Lexmark etc.). The price of original consumables is higher because of popularity of its producer and because the producer pawns the main part of his profit to the consumables.

Compatible consumables - are those similar with vendors product, which have been produced by another producer, not the company which has produced the printer. The use of compatible cartridges is profitable especially for the final consumer. Using compatible product he spares his facility to which since time he can gain one more printer.

As the original, so and the compatible cartridges can be refilled after the use. In most part of cartridges water based inks are used. However line of HP, Canon, Epson cartridges are filled with pigment inks. Different composition of inks provides differences of printing quality, and determines the type of paper carrier while printing. It is recommended to use its own type of ink for each cartridge. It provides better color transmit and higher quality of printing. There are also universal inks, which approach for refilling of broadly line of cartridges (but not all contract!!!).

2. Can use of not original consumables spoil the printer?

Of course, use of low quality consumables can cause to littering of printer because of spilling of a toner, caused by breach of hermeticity of the cartridge. This can bring with it premature wear-out of mechanism of the printer and bring to significant deterioration of printing quality. So don’t hurry in acquisition of strangely law coasting cartridges and properly interest about the warranty obligations of the vendor of such cartridges.

3. The advantages and disadvantages of SUIP (systems of uninterruptible ink presenting)

CISS (Continous Ink Supply System)- consists of cartridges, united with multi-server train with capacity of ink. During seal automatic unceasing presenting of ink occurs in to the cartridge. The Capacities of CISS are miscellaneous volume, starting from 50 ml. and finishing with greater capacities as 500 ml., which exceeds the capacity of a usual cartridge for several times.

It’s possible to use CISS as in the office which will allow to spare vastly on seal of documents, so as at home CISS will suit for printing photography fine. All this is reached thanks to data in the system using inks of alternative producers, which coasts much lower than original inks and do not yield them on quality.

The advantages of Continous Ink Supply System

- High stability of seal quality - is provided by constancy of the pressure in printing head of the printer, which does not depend on decreasing level of the ink in capacity-donor,

- Increasing the capacity of the printer - no necessities to spend time to change the cartridge, to clean printing heads,

- Reduction of the cost of the seal for 2-50 times (depending on a printer type). However you should take into account that in case of qualitative seal, the cost of the photo paper forms the main part of the imprint cost.

- Increasing the safety when printing - absence of risk of mortality of printer‘s printing heads because of hit of the air when changing the cartridge,

- Increasing the resource of printing heads,

- Seal of greater volumes without risk of interruption because of ink completion of the cartridge

- Possibility of renewing the spare of the ink of different colors in accordance with their real consumption while it’s necessary to change the standard three-colored cartridge when only one of three colors is finished.

Disadvantages

When moving the printer you’d better to perform maximum caution. Otherwise displacement of capacities on height can cause to suffuse of ink along whole printer of raised differences of the pressures.

4. What is cartridge refilling?

The Process of cartridge refilling includes:

- primary testing of the cartridge

- full stripping of the cartridge and its clearing from remainder of the toner

- refilling of cartridge with high-quality toner

- assembly

- output checking of quality and testing of filled cartridge

Cartridge refilling is a process, that vendors of the original consumables don’t love. Why? They lose money on this, and the users spare, moreover greatly. Simply talking refilling the cartridge, the body stays the same, only toner is changed, and all the other spare parts pass preventive clearing – here where the economy comes from. As a rule laser jet cartridge holds 2-3 refilling, after that reconstruction should be made.

5. What is “cartridge reconstruction”? Cartridge Reconstruction differs from its refilling that when recovering not only toner is changed, but also subject to wear-out components of the cartridge - a drum (OPC Dram, Photoreceptor), rackel (Wiper Blade, Cleaning Blade, cleaning edge) and if required, the other components - PCR (charging gross) etc.

6. What can cartridge refilling cause?

Many clients, choosing between buying a new cartridge and refilling of perfected ones, ask if refilling the cartridge is bed for the printer. This is because many sellers of the organizational technology categorically do not recommend to refill cartridges, motivating that it harms the device.

Posteriory we can say - qualitative refilling does not influence to the resource of the device. But spare on this client gets rather essential. For all the history of our work not a single refilled device has came out of formation because of faulty refilling. It’s possible to fill the cartridges repeatedly, changing through 2-3 refilling the drum or other spare parts if necessary.

The Maximum amount of the refilling, made by us on 1 cartridge, has exceed 80 refilling (for HP LJ 1010) and even after such amount of refillings, the cartridge qualitative prints and doesn’t pour the toner inside the device. The Advantage at a glance is 80 refillings 80*5000AMD=400000AMD, but when buying a new cartridge it’s going to be 80*30000AMD=2400000AMD. The Difference forms 2000000 AMD or approximately 34 new printers.

Other deal if the cartridge is filled unqualified, from it heavily pours the toner, drum and the other grosses are not swabbed, than this can bring to output of some details of the device from formation. But even herewith, refilling the cartridge rakish dips the repair and usage of the device.

7. How to consider what to do, refilling or reconstruction?

As a rule, laser jet cartridges hold 2-3 refilling, after that it should be reconstructed. There are some symptoms, basing on which it’s possible to define what to do, reconstruction or refilling:

Faded imprint, in some places text almost is not seen - it signs that toner is finished, you can get the cartridge and shake it, it’ll help for some time, but it’s already time to reconstruct or refill.

Vertically black bands in different places of the sheet, but most often on edge - sign of the wear-out of the drum - it is necessary to do reconstruction.

Horizontal dark bands - sign that drum is lit, possibly you have kept the cartridge without the black package - it is necessary to do reconstruction.

Gray background on whole sheet, "toner marks (indications)" - possibly the rackel (wiper blade) is damage - it is necessary to do reconstruction.

Vertical thin bands along whole sheet - magnetic gross is damaged (Mag. Roller, Developer Roller) - it is necessary to do reconstruction.

Defect of the seal reiterative in 3х-4х places on length of the sheet, herewith the rest imprint is normal - a mechanical damage of the drum (break), occurs in consequence of mechanical damage of the cartridge (have dropped or tried to insert in to the printer wrongly) - it is necessary to do reconstruction.

Cartridge clamors when working (squeaks) - possible, the rackel (wiper blade) is wearied out - it is necessary to do reconstruction.

8. What inks to chose?

After decision of installation of CISS or fuelled cartridge, this question appears .

The question of choice of inks is not ambiguous, it’s better to approach to it complexly and not to yield on provocations.

The main criteria of choice of the ink is:

Seal quality - includes color transmit of the ink (without grading): fluidity of the ink on a usual paper.

Stability of imprint to the external ambience (long-term). These questions are individual for different printer models and paper types (photo paper), on which you plan to print.

Accessibility and price - the ink should be available to acquisition. If a problem accurse to one seller with a given ink, it will be possible to buy them in an other place. The question of the price each solves for itself, but it must be at least reasonable.

If you already use the ink of some producer and it’s suitable for you, you’d better use them further more as the transition of an other ink concerned with certain difficulties and expenses.

9. What does laser jet cartridge’s drum’s speed of wear out depend on?

- Paper quality – the better the paper is, the longer drum serves,

- Paper density – the thicker the paper is, the more is its influence on the paper and the less drum serves,

- Printing intensity – the intensive the cartridge is used, the faster drum spoils,

- Use of stickers – stickers make additional load on the drum, special stickers should be used for laser jet printing

- Use of branded forms – many companies use branded forms (printed by color printer or in printing houses) – such as stickers it makes additional load on a drum, moreover that the additional load goes to the same part of the drum,

- Use of “circulating” (papers that are clean from one side) the paper passes through the drum by its used side, which causes to fast spoil of the drum,

- User’s culture – should take care of printer, conduct cleaning and preventive maintenance in time, not to load more than declared capacity.

Cartridge's construction

Cartridges are divided to several types. The most wide-spreader are cartridges consisting of two parts - bunker of departure and bunker of toner. Bunker with departure is intended for cleaning of drum from remainder of the scene, remained after copying on paper. Also for the further charge of the drum. This part of cartridge consists of the drum, doctor blade (cleaning blades), roller of the charge of the drum.

The drum – serves for imaging and carrying the scan to the paper. The resource of the drum depends on several factors, such as paper, toner quality, and on conditions of other parts of the cartridge. The drums resource is enough for 2-3 charging of the cartridge.

The roller of drum charge ( PCR ) – serves for making the potential on the drum. Drum’s charge roller’s resource mainly depends on producer of the cartridge.

Doctor ,WIPER BLADE

PCR

REC.BLADE

The rackel (the cleaning blade) is intended for removing the scene remainder from the drum, not crossed to the paper in the result of carrying the scene. Rackel presents itself a metallic plate sticker with silicone blade. For reduction of friction on the drum rackel is covered by talc. Rackel has a big resource and as a rule is damaged because of a stranger subject getting inside cartridge.

The second part of the cartridge, so-called bunker with toner, consists of magnetic gross, edge and reducer. Basically the dosing out edge and bushings of the magnetic gross are being wear-out. In not original cartridges these detail mortality not even having perfected its factory ink filling. Óñòðîéñòâî êàðòðèäæà

Useful information about care for printer and storage of cartridges

Don’t keep the cartridge

- under influence of the straight sunshine

- in temperature higher than 40°С

- in places with sharp swings of temperature and moisture

- in a car within long period of time

- in places with raised of the salts in atmosphere

- in places with raised dust.

Recommendations about keeping the cartridge

- Until you decide to use the new cartridge, keep it in the package

- Do not touch the cartridge without emergency! Do that when you decide to take it out for refilling or cleaning the cartridge! If the cartridge is already extracted keep it in the hermetic package without fall!

- The cartridge won’t print fault-free if keep it without the package for a long period of time.

Care for the printer

- keep the staff order of the switching off the printer,

- if within several days You have nothing to print, anyway don't care missing on seal at least one - two pages, this will make possible to avoid drought of sniffled ,

- if during seal network feeding disappears, wait for its reconstruction and immediately switch the printer off, using network stand-in,

- take out the cartridge only when changing,

- do not fill the cartridge yourself,

- and do not wash the mechanism of printer itself, including its head, with alcohol containing liquid (only distilled!) as this brings destruction of the sniffled covering.

History of printers

History of printers started from the moment when the first cave man has painted a mammoth with a piece of coal on the wall of his dwelling. But we won’t look so far. History of printers started from the moment when the first cave man has painted a mammoth with a piece of coal on the wall of his dwelling. But we won’t look so far.

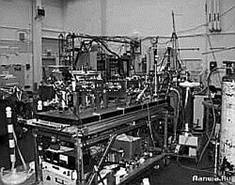

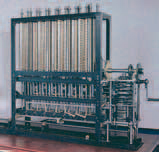

The first “printer” (if it’s possible to call printer) have been created with the first “computer” (if it’s possible to call computer). Two in one :). Great-grandfather of these device came up from distant 1834 (but the development began in 1822). Its inventor became well known Charles Babbage. Device Invented by him has got the name of Difference Engine (multifunctional machine). It was intended for use in navigations, designing, bank deal. This was a present mechanical computer, capable to print automatically! Regrettably, in that time working model was not built as well, it has been produced 150 years later. The London Sciences Museum Employees, under the direction of its director Drone Swad, have collected the device on drawings of the author, consisting of more then 4000 details with weight of 2.5 tons. Difference Engine could solve the protozoa equations and unseal the results on the paper.

Charles Babbage The earliest printer of Hewlett-Packard, presented in Washington museum Charles Babbage The earliest printer of Hewlett-Packard, presented in Washington museum

Petal printers

With appearance of the first electronic computer in the 50s of the last century need of saving received results of the calculations appeared. Specially trained people sat behind printed type-writer for that work and printed received information. Certainly, in a certain time the idea to connect the printed type-writers to the computer came to people. And in 1953 Remington-Rand corporation created the first printing device for UNIVAC computer (Universal Automatic Computer), and it got the name UNIPRINTER. It printed 600 lines per minute (130 signs on each line).

First mechanical printer

This monster mainly reminded printing type-writer and had work principle likely with it. When pressing any key, metal “pit” with a letter beat to the paper through dying tape, thereby leaving its print on it. Work principle of first printers was of the same way, you just didn’t need to press keys. The main element of the printer was the disk like daisywheels, in the end of petals of which symbols were inflicted. The disc revolved around its axis parallel with the paper. Striking mechanism beat the petal, which in its turn, beat the paper and left a print on the paper through the dying tape. Changing the disk with symbols you could get another font and inserting another color tape besides black you could get color print. Because of such construction such device has got the name of petal printer.

By that time Reynold B. Johnson occupied making of printing matrix for IBM printer. And in 1954 then again in 1955 cyan giant alternately presented two printer models printing 1000 lines per minute (100 symbols per line). But both models turned out to be unreliable and haven’t got spreading.

A little bit later in October of 1959 IBM 1403 printer was presented to the world. Their device printed four times faster than its rivals, and had unexcelled printing quality. The Mechanism of the seal differed from the rest printer models though it also had exactly the same type symbol set, inflicted on a paper through the tape. In IBM 1403 all symbols were situated in one row, and each had its striking mechanism. The printer could print up to 1400 lines per minute (132 signs on line (this is approximately 23 pages per minute! 3 seconds per page!!!)). Engineers working with this technology tell that when it started printing the results of the next calculations, the whole floor covered with thick layer of papers for several minutes, literally flowing out of the printer on enormous velocity. The Amusing particularity of the device was that when printing different symbols printer published sounds of different tonality. The Engineers enjoyed that, selecting and printing certain combinations of letters, forced the printer to play "music" if it’s possible to call so. Engineers have managed to obtain comparative reliability and speed of their device, but the main defect still remained: petal printers could not print graphics, published loud noise when functioning and reliability as before left “to wish better”. By the way, in Soviet Union instead of “printer” Alphabet digital printing device (ADPD) name was used. At present similar printers are not used.

Matrix Printers

Matrix printers (Dot Matrix Printer) are the logical continuation of petal devices. Difficult principle of printing is used in them. However symbols are formed from point set. “Any symbol and any scene can be formed from points”- that’s the principle of matrix and the rest printer types. Matrix printers had printing head in which needle set was placed. Needles like letters in petal printers knocked to the paper through dying tape forming scene this way.

The author of the first matrix printer was Seiko Epson corporation, which in 1964 developed printer mechanism which was printing in time. However greater producer of such printers became Centronics Data Computer corporation in 70-s. In 1970 they have developed matrix printer which got name of Model 101. For printing set from 7 needles was used in it (each symbol had 5x7 point size, that’s why the printer started to be called matrix), and it might print by speed of 165 symbol per minute. The coast of such “toy” formed $2995. Then in 1977 Micro-1 model was made (240 symbols per minute and with coast of $595). A year later Epson presented TX-80 printer, which had a huge success (mainly because of IBM corporation, which started the output and sale of this model on OEM-licenses).

One of the first matrix printers

By that time technologies didn’t stay the same place, printers with 9, 12,14,18 and 24 needles appeared. All this modifications were made for increasing the seal quality. So appeared the notions: LQ (Letter Quality) and NLQ (Near Letter Quality). At the end of 70-s first color matrix printers appeared. Four color printing tapes were used in them for reduction of different colors. But such printers have not got spreading.

The first real home printer became ImageWriter printer from C. Itoh Electronics company which was developed in the late 1976, but was presented together with Apple computer in 1983 by price of $675. At the same time to the list of existing printer producers joined such monsters like NEC, Oki data and TEC.

Up to present technology has reached almost unchanged. We face them every day, whenever they print a cash draft in every shop. As the seal on matrix printers is very cheap so it doesn’t hurry to abandon us.

Thermo seal

Unfortunately such printers couldn’t win the market, anyway they are met rather often, they are used for example when printing by fax or check out the counts in teller machines. With its action principle it remind the matrix printer, with the difference that here the needles are changed with heating elements, except this such printer needed special thermally sensitive paper. Basically the last fact limits the range of usage of such technology.

Thermo printers have evolution history much longer in contrast with matrix ones. Their history have started in 1988 with the first relatively ingenious IBM Quiet Writer model. In former SOVIET UNION first and, probably, single broadly used model was DCIP (the device of the conclusion to information printing) "Electronics MS 6312". The Quality of its seal reached 160 points per inch.

Ink Jet printers

Matrix printers are good for sure, but printing on them is very noisy and the result is not good enough. Everyone wanted to have a printer which would print quietly and qualitative and herewith would be cheap enough. Work principle of ink jet printing is as old as the printer of Charles Babbage. In late XIX century Nobel prize laureate on physicist lord Reilly studied the disinteration of stream liquids and drop shaping. But this technology have been realized only in 1948, in the laboratories of Siemens company.

There are only three methods of printing which are used in ink jet printers- piezoelectric method (is used by Epson and Brother companies), method of gas bladders (Canon) and drop-on-demand method (Hewlett-Packard). In all the devices reservoir with paint is used, on the bottom of which there is a small hole (nozzle).

At piezoelectric method of seal in the nozzle flat piezocrystal connected with a diaphragm is installed. When current is given to piezocrystal, it spreads and presses on the diaphragm. Thereby a droplet is formed, which is popped on paper. Such as a small pump.

In the gas bladders method (name of bubble jet technology) piezocrystal isn’t needed – instead of it heating element is used, which beats up the ink in the snot till temperature of 300-500 degrees in result of which gas bladders are formed that pomp up the ink to the paper.

The drop- on-demand method is likewise with the gas bladders method – a beating element is also used in it. Here is just the temperature a little lower and to the paper doesn’t get the drop, but a phial pair.

But let’s return to the story. First the piezoelectric method was created. However the idea didn’t go any further than theories for a long time. Only in the beginning of 70-s the first really working systems of ink jet printing appeared. One year later Siemens presented an ink jet printer for personal computers. But in 1978 Canon has declared about the development of Bubble Jet technology. A little later Hewlett-Packard declares about its drop-on-demand seal method. But technology from HP was realized in printer only in 1984, when the company has presented device of Think Jet series, which conquered the market quickly.

Later in the beginning of 90-s Hewlett-Packard has got the patent for the color ink jet scan. They decided to mix together three colors (blue (cyan), purple (magenta) and yellow (yellow)), thereby getting any tone. But first ink jet printers for personal computers appeared in Stylus Color series, from Epson.

Laser jet printers

Many people today prefer exactly this type of printers. And that’s not strange: such printers are not only compact and firm during work time, but at the same time don’t require frequent change of the cartridge. One refilling is enough for 1.5-20 thousand printing pages in dependence with a printer model and density of graphs. If to add possibility of independent and comparatively uncomplicated refilling of consumables, that reason of such choice becomes obvious. The only defect of such printers is an enormous cost of their "color variety".

If peek to the past, we can see that technology of laser seal appeared earlier, than matrix printers. In 1938 Chester Carlson invented a seal method, which got name of electrography This principle is used in all modern laser printers, and it is concluded in the following: on aluminum tube (drum), covered with a photosensitive layer, a negative steady-state charge is inflicted. Hereon a ray of laser passes on the drum, and in that place, where it’s necessary to print something, removes the part of the charge. Whereupon on the drum a toner is inflicted (this is a dry ink, consisting of mixture of resins, polymer, metallic shaving, coal dust and other chemistries), also having a negative charge, and therefore adhering to the drum in that places, where the laser passed and removes the charge. Then everything is simple: the drum rolls on paper (having a positive charge) and leaves the whole toner on it whereupon the paper falls into the stove, where under influence of a high temperature the toner is firmly being very hot to the paper. For color scene printing all the colors are inflicted on the drum by turn, or the seal occurs in 4 passages (for printing black, blue, purple and desired colors). Such print method is used in copiers and some faxes.

A similar system is also used in light diode printers, however instead of the laser still a line with light diodes – LED scan technology (Light Emitting Diode) is used.

The laser printer itself appeared the following way: certain Gery Starkweather, employee of Xerox company, decided to use technology of the copy device for creation of the printer. So began the development of the first laser printer at the beginning of 1969. But it has been presented in November of 1971. The device was called EARS but it didn’t come to life. If believe the documents, the first official laser printer identified Xerox 9700 Electronic Printing System, and was released in 1977. At the same time IBM assures that in 1976 their IBM 3800 laser printer was already printing with all might in South American Data Centre F. W. Woolworth.

Later, in May of 1981, Xerox presented Star 8010 computer, in composition of which latest developments were included, such as WYSIWYG-text editor, graphic editor, editor for combining text and graph, and of course the laser jet printer. All this pleasure coasted only $17000. It was some kind of home printing house.

Three years later Hewlett-Packard produces a laser jet printer, with 300 dpi permit and with coast of $3500. The same year Apple presented experimental models of its LaserWriter printer to such companies like Lotus Development, Microsoft and Aldus. And in 1985 and 1986 years Apple LaserWriter and LaserWriter plus printers appeared accordingly. In 1990 Hewlett-Packard’s LaserJet IIP printers started to coast less then $1000 for the first time. And in laser jet III series started the usage of the best permit technology (RET - Resolution Enhancement Technology). Two years later the same HP starts the sale of really public Laser jet 4 printer, which besides low price had 600 dpi permit. But the same year Lexmark company replaced HP in the market of laser jet printers producing Optra series devices with 1200 dpi permit.

Color laser printers appeared only in 1993. QMS company presented Color Script Laser 1000 printer for only 12,499 backs. Two years later Apple produces its Color Laser Printer 12/600PS for only $7.000.

Laser jet printers are much more cheaper now. They gain more popularity, however they are not so cheap yet to compete with ink jet printers.

Printers today

Seal technologies, invented in the last century didn’t change much. The technological process is being improved, number of points per inch increases, the quality and speed are improving. But not even essential changes in the printer world have occurred.

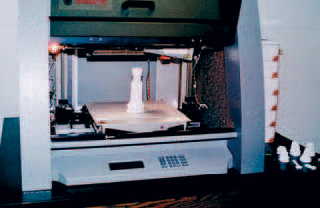

Three-dimensional printer

The last revolution in scan occurred in 80-s, when the three-dimensional printer was developed. First three-dimensional printers were similar on machine tools, which turned things of necessary form from a piece of wood or plastic, but than new really 3D printers appeared. Such printers made three-dimensional objects layer by layer (each layer could be up to 16 micron of thickness) inflicting the polymer on the necessary places.We can say with confidence that it’s early to dot on the development of the printing device. The Matrix printer has reached its technological limit, but this is impossible to say about the ink jet and the laser jet printers. Each day existing models are being improved and updated, making their contributions to the history of printers.

Compatibility table

We want to give some usefull information to our readers about the qartridges and printers compatibility, to help them define in the compatibility table and choose a qartridge for their printers themselves.

In this section you can find information about the compatibility of consumables and different models of various producers.

|

• Complaints, offers, remarks

• Usefull information

Have you find the information you was looking for?

|

|